Product Information

- Category: Packaging

Types of Packaging

Packaging

Vacuum Packaging

Vacuum packaging is a modern and efficient method of preserving and storing various types of products, ranging from food to electronic components. This technique involves removing the air from the packaging before sealing it, creating a vacuum environment inside. By eliminating oxygen, which is the primary factor that leads to spoilage and degradation, vacuum packaging helps extend the shelf life of perishable goods. This process also helps protect products from external factors such as moisture, dust, and contaminants, ensuring their quality and freshness over a longer period.

Vacuum packaging is widely used in the food industry for items like rice, wheat, and vegetables, as well as in industries where maintaining the integrity of sensitive materials is crucial. The convenience, preservation benefits, and reduction in food waste make vacuum packaging an essential innovation in modern packaging technology.

Benefits of Vacuum Packaging:

1. Longer Shelf Life: By removing air, there is no oxygen in the bag for weevils, bacteria, or fungi to survive.

2. No Damages: The bag’s strength has been improved massively! Plus, by having no air there are fewer damages as when pressure is applied on bags during loading/offloading air is not looking for space to get out.

3. Need Less Storage Space: By removing air, we have made bags flat, meaning you can stack more bags in the same amount of space. This is very good for customers with small stores e.g., restaurants, small supermarkets, or wholesalers.

Packaging

Jumbo Vacuum Bags

Jumbo bags, also known as bulk bags or FIBCs (Flexible Intermediate Bulk Containers), are large and highly durable containers designed to handle and transport a wide range of bulk materials. These bags are commonly used in industries such as agriculture, construction, mining, and manufacturing, where large quantities of materials like grains, minerals, chemicals, and construction aggregates need to be efficiently transported and stored.

Jumbo bags are typically made from woven polypropylene fabric, which provides both strength and flexibility. They come in various sizes and designs, including different lifting and closure mechanisms to suit the specific requirements of different industries. The versatility of jumbo bags makes them an ideal solution for simplifying the handling and storage of bulk materials, streamlining logistical processes, and ensuring the safe and economical transportation of goods across various sectors.

Packaging

Jumbo Vacuum Bags with CO2 Fumigation

Jumbo bags with CO2 refer to the use of carbon dioxide (CO2) as a method to preserve and protect the contents of these large bulk containers. This technique involves introducing controlled amounts of carbon dioxide gas into the jumbo bags before sealing them. The CO2 displaces the oxygen within the bag, creating a modified atmosphere that helps to extend the shelf life of the stored materials.

This process is particularly useful for products such as grains, seeds, and other perishable goods, as it can inhibit the growth of spoilage microorganisms and slow down the oxidation process that leads to deterioration. By reducing the oxygen levels, jumbo bags with CO2 can help maintain the quality and freshness of the contents, thereby reducing waste and improving the overall efficiency of storage and transportation in industries dealing with bulk materials.

Packaging

Wooden Pallet Treatment with CO2

Wooden pallet treatment with CO2 has emerged as an environmentally friendly and innovative approach to pest management and sanitation. This technique involves exposing wooden pallets to controlled carbon dioxide (CO2) environments, effectively eliminating harmful insects, fungi, and pathogens that may be present on the wood surface. The use of CO2 for pallet treatment offers several advantages, such as being chemical-free and non-toxic, making it a safe option for both human health and the environment. Additionally, CO2 treatment does not leave residue or alter the physical properties of the wood, ensuring that the pallets remain structurally sound for their intended purposes.

As sustainability gains prominence in various industries, the adoption of CO2 treatment for wooden pallets showcases a forward-thinking approach that combines effective pest control with eco-conscious practices, contributing to the overall improvement of supply chain management and product safety.

Packaging

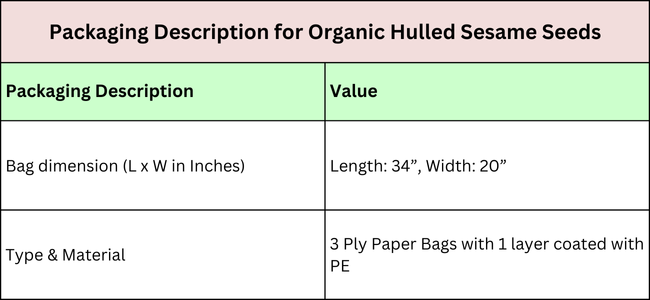

Paper Bags

Our high-quality sesame paper bags are designed to securely store and transport sesame seeds and other dry goods. These robust bags are made from durable, eco-friendly paper, ensuring the safety and freshness of the contents. The bags feature a sturdy construction with a reliable sealing mechanism to prevent spillage and protect against moisture.

Key Features:

- Material: Eco-friendly, durable paper

- Design: Strong and secure, with a reliable sealing mechanism

- Usage: Ideal for storing and transporting sesame seeds and other dry goods

- Capacity: Generous size to hold large quantities

- Eco-Friendly: Made from recyclable materials